Most Commented

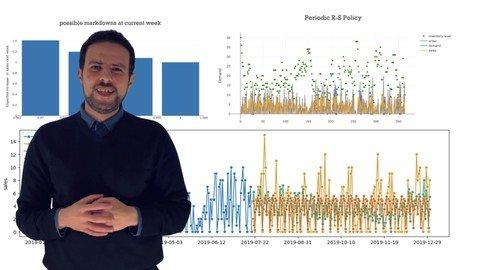

Stock Control And Inventory Dynamics With Excel & Python.

Description material

Published 8/2023

MP4 | Video: h264, 1280x720 | Audio: AAC, 44.1 KHz

Language: English | Size: 7.03 GB | Duration: 14h 52m

Apply the Best forecasting model and inventory policy for all the Products in your Assortment and much more!!

What you'll learn

Apply EOQ policies with discount , promotions , multiple suppliers and multiple products.

Simulate inventory policies for unlimited number of products.

Know which forecasting is better for your products.

Know which inventory policy is better for your products.

understand the impact of aggregation and dis-aggregation on inventory.

Understand How inventory interact with demand ?

Work with the specialized inventory library in python Inventorize.

apply markdowns on seasonal produce to move inventory

Requirements

Anaconda (How to install inside)

Microsoft Excel

Description

Hello :)The course has two quizzes, practical exam and a lot of excel /Python practice on real inventory cases.With the ever increasing reliance of supply chain management to deliver. supply chain jobs become one of the highest in demand jobs of the twenty first century, it is one of the jobs that will not be affected by automation because of its nature as a critical thinking and resilient profession. And with the procurement function In supply chain being the heart and soul of feeding the supply chain with product/material, distribution is equally as important because it streamlines the flow of products to the end customer.Wwe explain in detail analytically and practically the inventory side of the supply chain.I am excited to share with you this course that talks about inventory in great detail, I can go as far as saying that the applications inside this course is not anywhere as the inventorize package that is developed by me and has more than 60000 downloads thus far is developed by yours truly.Inventorize package has a lot of functionalities in my daily consulting activities with multi-national retailers and I would love to share its nitty gritty details with you. Not only this the course discuss the basics also and ascends step by step to the more advanced first by excel and then using Python.with this course, Based one students demand.we take it one step further; we combine Supply chain , Devops and Data science to make a comprehensive inventory course for you. Don't worry If you don't know how to code, we learn step by step by applying supply chain analysis!*NOTE: Full course includes downloadable resources and Python project files, Setup Codes, lifetime access, and a 30-day money-back guarantee.In this course we will get to know :1- Types of inventory, EOQ and its variations and how to calculate inventory costs. (Excel)2- Inventory KPIs and how to force an inventory policy with a desired fill rate/service level. (Excel)3- Aggregation and disaggregation affect on inventory.(Excel)4- Python crash chapters if you do not know python.5- Create an EOQ program in Python.6- assigning desired fill rate with Goa seek function (Python).7- Forecasting in python.8- Inventory simulations in Python.9- Forecasting with inventory simulations in Python.10- Inventory for seasonal products and how to apply markdowns for them.Hope you enjoy & Happy Supply Chain mining!HaythamRescale AnalyticsFeedback from Clients, Training and other online courses:"I attended this course with high expectations. And I was not disappointed. It´s incredible to see what is possible with Python in terms of supply chain planning and optimization. Haytham is doing a great job as a trainer. Starting with explanation of basics and ending with presentation of advanced techniques supply chain managers can apply in real life."Larsen BlockDirector Supply Chain Management at Freudenberg Home and Cleaning Solutions GmbH"In Q4 2018, I was fortunate to find an opportunity to learn R in Dubai, after hearing about it from indirect references in UK.I attended a Supply Chain Forecasting & Demand Planning Masterclass conducted by Haitham Omar and the possibilities seemed endless. So, we requested Haitham to conduct a 5-day workshop in our office to train 8 staff members, which opened us up as a team to deeper data analysis. Today, we have gone a step further and retained Haitham, as a consultant, to take our data analysis to the next level and to help us implement inventory guidelines for our business. The above progression of our actions is a clear indication of the capabilities of Haitham as a specialist in R and in data analytics, demand planning, and inventory management."Shailesh MendoncaCommercial lead-in Adventure AHQ- Sharaf Group" Haytham mentored me in my Role of Head of Supply Chain efficiency. He is extremely knowledgebase about the supply concepts, latest trends, and benchmarks in the supply chain world. Haytham's analytics-driven approach was very helpful for me to recommend and implement significant changes to our supply chain at Aster group"Saify NaqviHead of Supply Chain Efficiency"I participated to the training session called "Supply Chain Forecasting & Management" on December 22nd 2018. This training helped me a lot in my daily work since I am working in Purchase Dpt. Haytham have the pedagogy to explain us very difficult calculations and formula in simple way. I highly recommend this training."Djamel BOUREMIZPurchasing Manager at Mineral Circles Bearings

Overview

Section 1: Introduction

Lecture 1 Introduction

Lecture 2 Types of inventory

Lecture 3 Cycle inventory

Lecture 4 Holding cost and ordering cost

Lecture 5 Zara and seven eleven

Lecture 6 EOQ

Lecture 7 EOQ-One product

Lecture 8 EOQ-same truck

Lecture 9 EOQ-many suppliers

Lecture 10 Algorithm for flexible order subsetting

Lecture 11 Algorithm for flexible order subsetting_part2

Lecture 12 Product subset part3

Lecture 13 Algorithm for product subsetting step 4

Lecture 14 Volume discounts

Lecture 15 Volume Discounts in Excel

Lecture 16 marginal discounts

Lecture 17 EOQ with limited time discounts

Lecture 18 Limited time discounts

Lecture 19 Demand Curve change with EOQ

Lecture 20 Summary

Lecture 21 Game plan

Section 2: Inventory aggregation, metrics and distribution.

Lecture 22 Introduction

Lecture 23 A brief on inventory policies

Lecture 24 Fill rate and service level for uncertain demand.

Lecture 25 Bike Co

Lecture 26 Bike Co, flow time and average inventory.

Lecture 27 Bike Co, Desired service level

Lecture 28 Bike co, cycle service level.

Lecture 29 Desired fill rate

Lecture 30 Inventory aggregation

Lecture 31 Shopico Example

Lecture 32 Scenario 1: Disaggregation

Lecture 33 Scenario 2: Aggregation

Lecture 34 HighMed

Lecture 35 HighMed Part 1

Lecture 36 HighMed Part 2

Lecture 37 Inventory Cost

Lecture 38 Which option is better?

Lecture 39 Temporal aggregation

Lecture 40 Conclusion

Lecture 41 Summary

Section 3: Welcome to Python

Lecture 42 Python!

Lecture 43 downloading Anaconda

Lecture 44 Installing Anaconda

Lecture 45 Spyder overview

Lecture 46 Jupiter Notebook overview

Lecture 47 Python Libraries

Lecture 48 inventorize

Lecture 49 Summary

Section 4: Python Programming Fundmentals

Lecture 50 Intro

Lecture 51 Dataframes

Lecture 52 Arithmetic calculations with python

Lecture 53 Lists

Lecture 54 Dictionaries

Lecture 55 Arrays

Lecture 56 Importing data in Python

Lecture 57 Subsetting Dataframes

Lecture 58 Conditions

Lecture 59 Writing functions

Lecture 60 Mapping

Lecture 61 For loops

Lecture 62 For looping a function

Lecture 63 Mapping on a DataFrame

Lecture 64 For looping on a Dataframe

Lecture 65 Summary

Lecture 66 Assignment

Lecture 67 Assignment answer 1

Lecture 68 Assignment answer 2

Section 5: Inventory with Python.

Lecture 69 Program for EOQ aalgorithm

Lecture 70 Revisiting BikeCo

Lecture 71 Cycle service level in python

Lecture 72 Expected item fill rate in python

Lecture 73 Goal seek function

Lecture 74 Desired fill rate

Lecture 75 Revisiting EOQ with many suppliers.

Lecture 76 Introducing the case in python

Lecture 77 EOQ with inventorize

Lecture 78 Step 2 and step 3

Lecture 79 global order frequency for product subsetting

Lecture 80 Total cost of the system

Section 6: Segmentation, classification and inventory simulations

Lecture 81 Inventory Dynamics intro

Lecture 82 Why we need segmentation.

Lecture 83 An example in Excel.

Lecture 84 Product classfication

Lecture 85 ABC dynamic with inventorize

Lecture 86 The long tail

Lecture 87 Category mix on multiple products

Lecture 88 Min max policy

Lecture 89 Min Q and Periodic Policy

Lecture 90 R_s_S and base_stock_policy

Lecture 91 Connecting demand with service level

Lecture 92 Running the simulation on all articles

Lecture 93 Understanding the results

Lecture 94 Assignment

Lecture 95 Assignment solution

Lecture 96 Summary

Section 7: Which forecasting is better for a specific inventory policy ?

Lecture 97 Introduction

Lecture 98 Forecasting demonstraion

Lecture 99 Max Policy

Lecture 100 Preparing the notebook

Lecture 101 Preparing for forecasting

Lecture 102 Forecasting our first sku

Lecture 103 Forecasting all SKUs

Lecture 104 Max_policy_Dynamic

Lecture 105 Inventory Comparison between KNN and ARIMA

Lecture 106 Assigning cycle service level and preparing for simulation.

Lecture 107 Running the simulation

Lecture 108 Which forecast is better in terms of inventory?

Section 8: Seasonal Inventory

Lecture 109 Intro

Lecture 110 Seasonal Products

Lecture 111 Point of Maximum profit

Lecture 112 How much I will sell?

Lecture 113 Dataable

Lecture 114 Critical ratio

Lecture 115 Critical ratio in excel

Lecture 116 What's actually happening ?

Lecture 117 Critical ratio in python

Lecture 118 Preparing the data for MPN.

Lecture 119 Creating margin of error.

Lecture 120 Applying MPN on all data.

Lecture 121 Conclusion

Lecture 122 Seasonal inventory summary

Lecture 123 Assignment solution

Lecture 124 Seasonal inventory answer

Lecture 125 Markdown model by J.Walker

Lecture 126 Markdown model in python

Lecture 127 Final note

Inventory Managers,Supply chain managers,Buyers,Demand planners,Supply planners,Retail planners

Buy Premium Account From My Download Links & Get Fastest Speed.

https://1dl.net/vqlhznh92dwm/Stock_Control_and_Inventory_Dynamics_with_Excel_Python.part1.rar

https://1dl.net/1wgx14hjyiyl/Stock_Control_and_Inventory_Dynamics_with_Excel_Python.part2.rar

https://1dl.net/629lll9qv06f/Stock_Control_and_Inventory_Dynamics_with_Excel_Python.part3.rar

https://1dl.net/ygt67kaobcgg/Stock_Control_and_Inventory_Dynamics_with_Excel_Python.part4.rar

https://nitroflare.com/view/CB2CA069719D193/Stock_Control_and_Inventory_Dynamics_with_Excel_Python.part1.rar

https://nitroflare.com/view/5D157F47D9BB22F/Stock_Control_and_Inventory_Dynamics_with_Excel_Python.part2.rar

https://nitroflare.com/view/B3E455BA326684F/Stock_Control_and_Inventory_Dynamics_with_Excel_Python.part3.rar

https://nitroflare.com/view/1771DE890D53CE5/Stock_Control_and_Inventory_Dynamics_with_Excel_Python.part4.rar

https://rapidgator.net/file/af95ff88ebde810f0638e0a7126a36d3/Stock_Control_and_Inventory_Dynamics_with_Excel_Python.part1.rar.html

https://rapidgator.net/file/6b7700a9e2d1eb7715898f1bc3f70334/Stock_Control_and_Inventory_Dynamics_with_Excel_Python.part2.rar.html

https://rapidgator.net/file/d36c40898aad181904f61bfc3cc8d83e/Stock_Control_and_Inventory_Dynamics_with_Excel_Python.part3.rar.html

https://rapidgator.net/file/5d1fa6ef9671b258ad41dc539e4e1744/Stock_Control_and_Inventory_Dynamics_with_Excel_Python.part4.rar.html

Join to our telegram Group

Information

Users of Guests are not allowed to comment this publication.

Users of Guests are not allowed to comment this publication.

Choose Site Language

Recommended news

Commented

![eM Client Pro 9.2.1735 Multilingual [Updated]](https://pikky.net/medium/wXgc.png)

![Movavi Video Editor 24.0.2.0 Multilingual [ Updated]](https://pikky.net/medium/qhrc.png)