Most Commented

Siemens Tecnomatix Process Simulate 2301 (x64)

Description material

File size: 6.38 GB

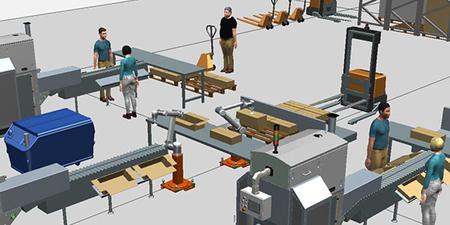

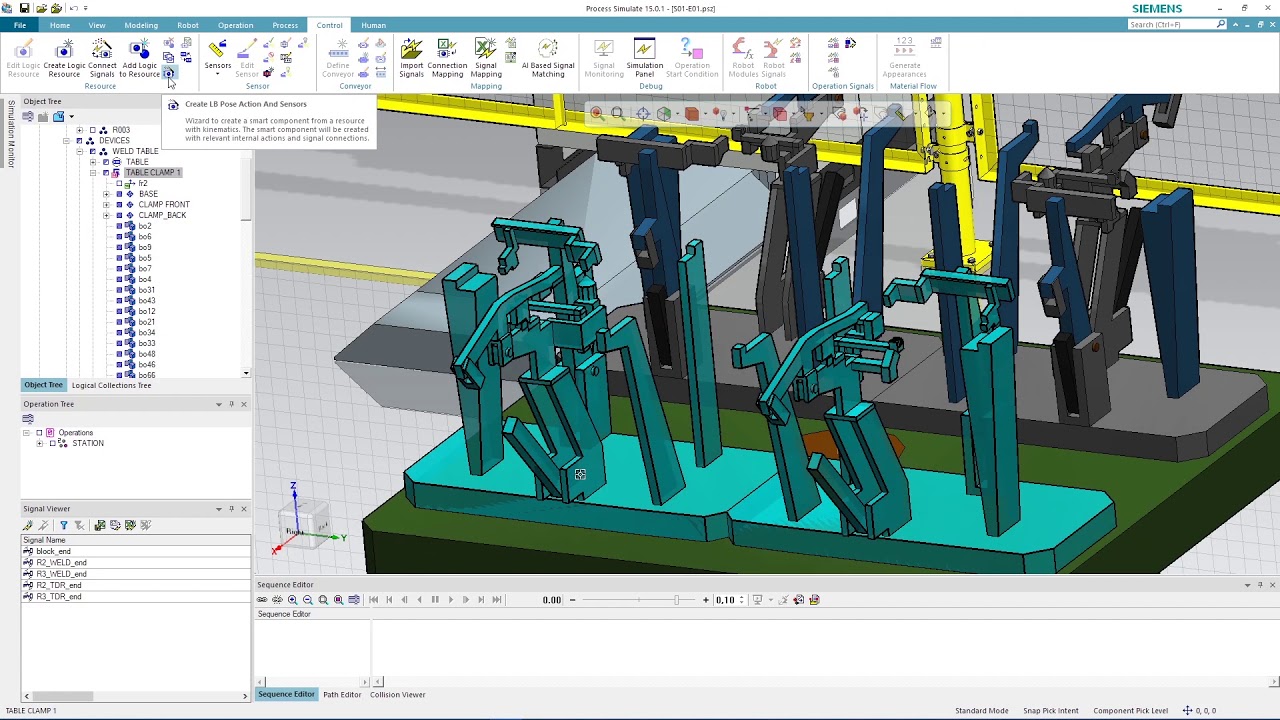

Siemens Tecnomatix Process Simulate is a solution for modeling and testing technological processes in a three-dimensional graphical environment. This solution provides virtual verification, optimization and implementation of complex manufacturing processes, allowing you to start production faster and improve product quality.

With Process Simulate, users verify the assembly process, eliminating possible collisions between elements of the production cell.

The main tasks solved by Process Simulate

Analysis of the product's assembleability, taking into account possible deformations of parts (for example, seals, etc.);

Analysis and optimization of the order of technological operations and transitions;

Volumetric (for example, collision) analysis of production lines;

Estimation of operation time;

Optimization of installation trajectories of parts and assemblies;

Ability to prepare graphic materials for assembly and maintenance instructions.

Process Simulate is fully integrated with the Teamcenter manufacturing platform, allowing technologists to reuse existing processes and create and evaluate new ones.

There are several editions of the product to work in different configurations

Process Simulate on eMServer - for working in conjunction with the Process Designer product and storing data in a specialized Oracle-based database.

Process Simulate on Teamcenter - for working under the control of the Teamcenter PLM system.

Process Simulate Standalone - for offline operation on a file system.

Process Simulate allows you to simulate robotic processes - spot welding, arc welding, laser welding, coating and sealing, machining, moving objects, etc.

When simulating manual operations, the Process Simulate Human module is used, which uses technology and a digital mannequin called Jack. The presence of a mannequin makes it possible to take into account ergonomic factors, ensure a rational layout of workplaces and eliminate excessive loads on the human operator.

The simulation realistically reproduces human actions, the operation of auxiliary equipment, robot controllers and PLCs.

In addition, the solution has an open software interface and allows you to develop your own plug-ins that expand functionality.

The Process Simulate Robotics module is used to develop control programs for robots and robotic cells and allows you to solve the following problems

Virtual commissioning;

Loading existing programs from the robot controller and uploading to the controller;

Optimization of robotic cell cycles to prevent mutual robot collisions;

Using robots from the library;

Creation of your own kinematic schemes.

Siemens Tecnomatix Process Designer is a solution for preparing, managing and storing process information.

This solution allows you to design new and reuse standard, previously tested and optimized processes and resources from the library, standardize and shorten the build planning process. A convenient user interface allows you to determine the assembly sequence and provides access to the tools necessary to create a digital mockup.

Process Designer also makes it possible to create various types of process documentation, including electronic work instructions, specifications and descriptions

Screen :

What's New

HOMEPAGE

https://plm.automation.siemens.com/en_us/products/tecnomatix/

Buy Premium Account From My Download Links & Get Fastest Speed.

https://ddownload.com/dewsv78cogdh/Siemens.Tecnomatix.Process.Simulate.2301.Win64-SSQ.part1.rar

https://ddownload.com/59kh5c8oxp0r/Siemens.Tecnomatix.Process.Simulate.2301.Win64-SSQ.part2.rar

https://ddownload.com/kxtbn0ukmkqm/Siemens.Tecnomatix.Process.Simulate.2301.Win64-SSQ.part3.rar

https://ddownload.com/5l25odu52uo6/Siemens.Tecnomatix.Process.Simulate.2301.Win64-SSQ.part4.rar

https://rapidgator.net/file/e5c95703fa8d554f356dae8625e31ae9/Siemens.Tecnomatix.Process.Simulate.2301.Win64-SSQ.part1.rar.html

https://rapidgator.net/file/c4e19884fa53c2cd4a9fb97740ab1502/Siemens.Tecnomatix.Process.Simulate.2301.Win64-SSQ.part2.rar.html

https://rapidgator.net/file/2b5f503997d265dfab838d8420d8ef2b/Siemens.Tecnomatix.Process.Simulate.2301.Win64-SSQ.part3.rar.html

https://rapidgator.net/file/bdf186d912e4f29bf303f33cbe70ba8d/Siemens.Tecnomatix.Process.Simulate.2301.Win64-SSQ.part4.rar.html

Join to our telegram Group

Information

Users of Guests are not allowed to comment this publication.

Users of Guests are not allowed to comment this publication.

Choose Site Language

Recommended news

Commented

![eM Client Pro 9.2.1735 Multilingual [Updated]](https://pikky.net/medium/wXgc.png)

![Movavi Video Editor 24.0.2.0 Multilingual [ Updated]](https://pikky.net/medium/qhrc.png)