Most Commented

Cimatron 2024.0 SP1

Description material

x64 | File size: 4.43 GB

Cimatron, the leading CAD/CAM software supplier for the mold & die industry has released version 2024 with stronger core capabilities across all areas of the product, while incorporating new technology through collaboration with Sandvik Coromant. Cimatron 2024 simplifies and automates many tasks for tool designers for higher productivity, and more options for digital connection.

CAD modeling for CNC

Cimatron has all the necessary tools for working with geometry, allowing you to edit imported models and create your own

Efficient rough milling

Easy-to-define roughing operations ensure constant tool load for maximum machining performance, taking into account the remaining workpiece material at each path point

High quality finishing milling

Cimatron optimizes the machining path according to the topology of the part to achieve high quality surfaces in the shortest possible time

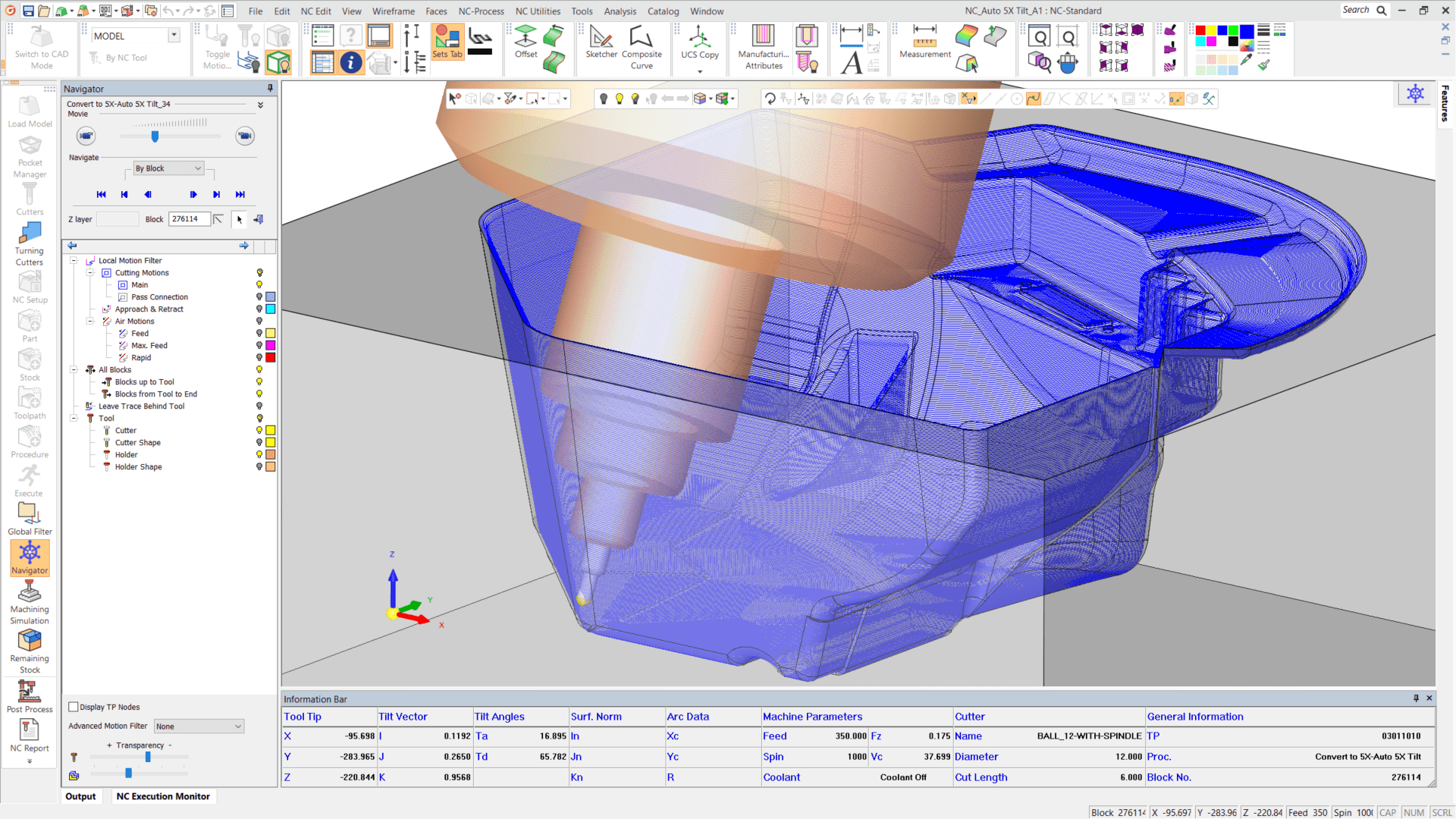

Five-axis milling

Cimatron continuous 5-axis milling strategies allow you to machine areas where positional milling is ineffective

Drilling automation

Automatic recognition and selection of the technological process for processing holes allows you to reduce the time required for developing control programs and manufacturing products

Feature Recognition

Automatic recognition of geometric elements such as open and closed pockets and grooves, holes and chamfers allows them to be sorted according to size and shape criteria for fast and safe processing programming

Turning and turning-milling processing

Cimatron provides the ability to program turning and turning-milling processing on turning and milling machines

High speed processing

Cimatron optimizes tool paths for high-speed and high-feed machining, allowing for maximum material removal during roughing operations and superior surface finish after finishing passes, helping to extend tool and equipment life.

Micro milling

Cimatron enables efficient, high-precision machining of miniature parts with small tool sizes

Support for special tools

Cimatron supports cutters with radius segments in the profile. Their use makes it possible to reduce processing time at the same scallop height and at the same time obtain a better surface quality

Programming Test Probes

Cimatron allows you to program control operations with measuring probes from various manufacturers and set the logic of actions based on measurement results

Visualization and verification of processing

Special Cimatron tools provide visual verification of the correctness and safety of generated processing paths

Postprocessors

Postprocessors for Cimatron provide the creation of control programs that take into account the characteristics of each machine and CNC system and eliminate the need for manual editing

Documentation generation

Cimatron reduces control program development and part manufacturing time by offering a wide range of dedicated optimization tools for various tasks and work steps.

Screen :

What's New

HOMEPAGE

https://www.cimatron.com/

Buy Premium Account From My Download Links & Get Fastest Speed.

https://ddownload.com/5v88esdcd4jk/Cimatron_2024_SP1.part1.rar

https://ddownload.com/ioapqkr80bza/Cimatron_2024_SP1.part2.rar

https://ddownload.com/jfzdz85z1oh3/Cimatron_2024_SP1.part3.rar

https://ddownload.com/71ppurvkkldx/Cimatron_2024_SP1.part4.rar

https://ddownload.com/cx3pqaninvg6/Cimatron_2024_SP1.part5.rar

https://rapidgator.net/file/d2df55e434fb7b793f7720e2751424a2/Cimatron_2024_SP1.part1.rar.html

https://rapidgator.net/file/9638e1f05e383c3a6d17bd285a654e9b/Cimatron_2024_SP1.part2.rar.html

https://rapidgator.net/file/cbe1febd25fe7e1698e70df31554afb0/Cimatron_2024_SP1.part3.rar.html

https://rapidgator.net/file/629edfe161b369028d5e4d5b9c20e41c/Cimatron_2024_SP1.part4.rar.html

https://rapidgator.net/file/cca17a9c779441d08979dce4e7e5f0a2/Cimatron_2024_SP1.part5.rar.html

Join to our telegram Group

Information

Users of Guests are not allowed to comment this publication.

Users of Guests are not allowed to comment this publication.

Choose Site Language

Recommended news

Commented

![eM Client Pro 9.2.1735 Multilingual [Updated]](https://pikky.net/medium/wXgc.png)

![Movavi Video Editor 24.0.2.0 Multilingual [ Updated]](https://pikky.net/medium/qhrc.png)