Most Commented

ANSYS 2024 R1 nCode DesignLife (x64)

Description material

File size: 2.11 GB

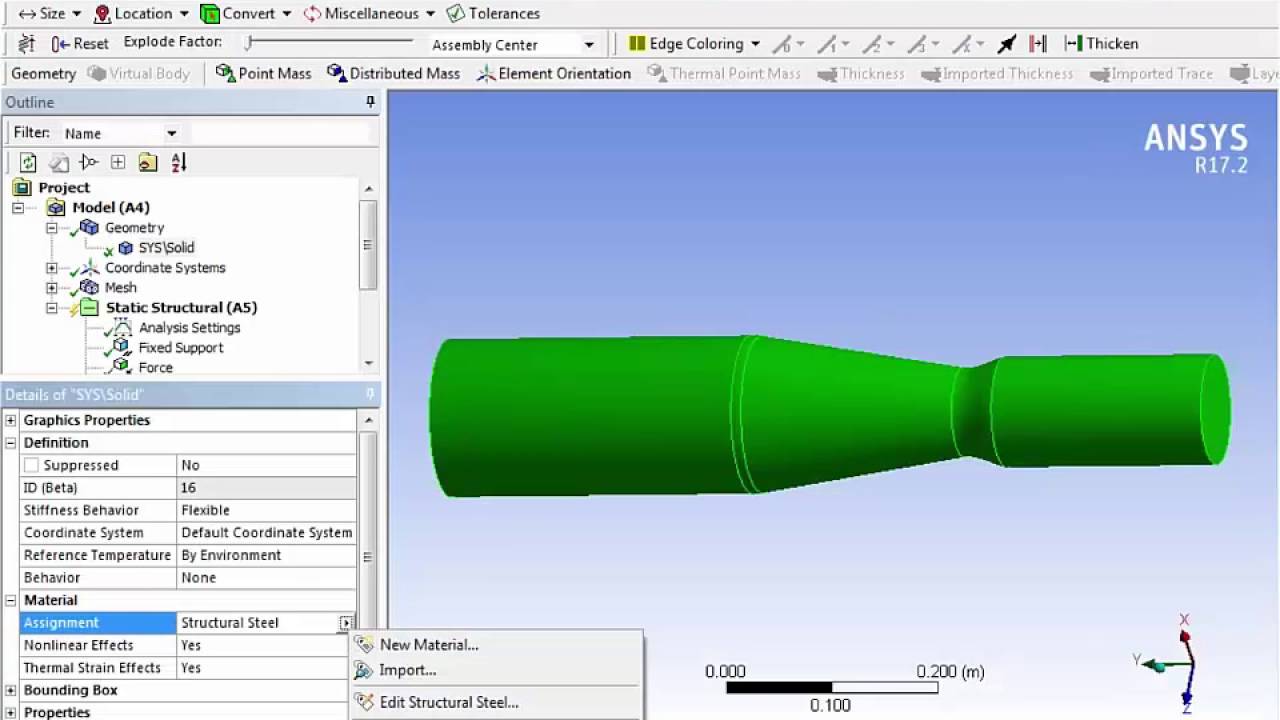

ANSYS nCode DesignLife works with ANSYS Mechanical to reliably evaluate fatigue life. Using the results of finite element analysis (FEA) from ANSYS Mechanical, it calculates stresses and strains, then cumulates damage from repetitive loading to determine a product's predicted life. You can quickly evaluate the effects of different materials and alternative geometries for new designs, and then optimize them for the product's expected usage — long before the first prototype is built.

Features

Full Integration into ANSYS Workbench

Easy Click-and-Drag Setup

Extensive Fatigue Material Library

State-of-the-Art Fatigue Modeling Capabilities

High-Speed Solver

ANSYS nCode DesignLife provides a comprehensive diagnostic fatigue process. It is the industry-leading tool for durability analysis, fully integrated in ANSYS Workbench for ease of use and smooth workflow for FEA fatigue analysis. Expert users can create complex loading "duty cycles" based on measurements that represent real-life forces on products; alternatively, they can use anticipated loading histories. Once created, the fatigue process can be captured and reused. Modified product designs can be evaluated without requiring fatigue expertise to determine the updated product life. Start-to-end automation removes the majority of errors and ensures consistency on the analysis done, especially in large organizations in which multiple engineers performing analysis.

Fatigue analysis process

Once created, the fatigue process can be captured and reused. Engineers without fatigue expertise can evaluate modified product designs to determine the updated product life. Start-to-end automation avoids the majority of errors and ensures consistency, especially in large organizations in which multiple engineers might be analyzing the results.

Ural Diesel Motors

Ural Diesel-Motor Works engineers used ANSYS nCode DesignLife fatigue analysis software to calculate high-cycle fatigue safety factors. They then ran the thermal-stress analysis again with the new design, exported the stresses to nCode DesignLife, and combined the results with a material model and a description of the repetitive loading that the product is expected to undergo during operation. nCode DesignLife captured the data, data flow and parameters in ANSYS Workbench and performed a comprehensive fatigue analysis using the stress-life approach.

E-Z-GO, a Textron Company

E-Z-GO engineers were given one week to redesign a utility vehicle frame to eliminate a bend that was causing manufacturing difficulties. Based on the results of the finite element analysis, fatigue life estimation and durability testing, the new utility vehicle frame design was released for production. This approach substantially reduced engineering costs and helped E-Z-GO get the new design into production faster.

Capabilities

ANSYS nCode DesignLife, the industry-leading tool for durability analysis, gives you a comprehensive diagnostic fatigue process to predict your product's operational lifetime. It is fully integrated into ANSYS Workbench for ease of use and smooth workflow. You can create complex loading "duty cycles" based on measurements that represent real-life forces on products, or use anticipated loading histories.

ATTENTION!

This version of nCode DesignLife requires pre-installed ANSYS 2024 R1 Win64 with fix from SSQ and uses ANSYS 2024 R1 Win64 licensing

In this regard, the functionality of this version is lower than in the similar Standalone version of HBM nCode 2024

Screen :

What's New

HOMEPAGE

https://www.ansys.com/

Buy Premium Account From My Download Links & Get Fastest Speed.

Join to our telegram Group

Information

Users of Guests are not allowed to comment this publication.

Users of Guests are not allowed to comment this publication.

Choose Site Language

Recommended news

Commented

![eM Client Pro 9.2.1735 Multilingual [Updated]](https://pikky.net/medium/wXgc.png)

![Movavi Video Editor 24.0.2.0 Multilingual [ Updated]](https://pikky.net/medium/qhrc.png)