Most Commented

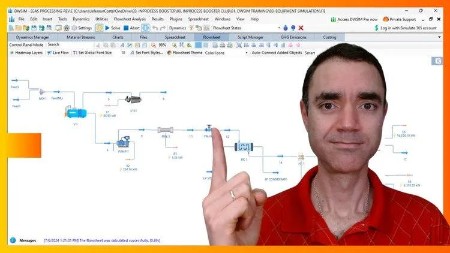

DWSIM Process Simulation: Mastering The Fundamentals

Description material

DWSIM Process Simulation: Mastering the Fundamentals

Published 7/2024

Duration: 6h32m | .MP4 1280x720, 30 fps(r) | AAC, 44100 Hz, 2ch | 3.22 GB

Genre: eLearning | Language: English

Complete set to start your chemical engineering career with DWSIM process simulation

What you'll learn

Be able to build, navigate and use different functions of DWSIM to build steady state process simulations.

Simulate a full process with vessel separator, compressor, pump, valve, pipe, heat exchanger and column

Understand process simulation under chemical engineer's point of view in plant design

Export heat and material balance for sizing of process equipment

Requirements

A background in chemical engineering (student, graduate or engineer) or allied engineering courses.

Notebook or desktop with internet connection (software will be provided for Windowns, MAC and Linux)

Description

This training program is designed to equip participants with the essential skills to effectively use DWSIM, a powerful chemical process simulation software. By the end of this course, participants will:

Build, Navigate, and Utilize DWSIM Functions:

Gain proficiency in constructing and managing steady-state process simulations using DWSIM.

Learn to navigate the user interface efficiently, exploring various tools and features to optimize workflow.

Master the use of different functions within DWSIM, enhancing simulation accuracy and efficiency.

Simulate a Full Process:

Develop the capability to simulate complete processes involving multiple unit operations.

Model a comprehensive process that includes essential equipment such as vessel separators, compressors, pumps, valves, pipes, heat exchangers, and columns.

Understand the interactions between different units and how to configure them within a simulation.

Understand Process Simulation from a Chemical Engineer's Perspective:

Acquire a thorough understanding of process simulation principles as applied to plant design.

Learn to analyze simulation results with a chemical engineer's insight, focusing on real-world applicability and design considerations.

Gain knowledge on how to optimize processes for efficiency, safety, and cost-effectiveness.

Export Heat and Material Balances for Equipment Sizing:

Learn to export detailed heat and material balance data from simulations.

Gain skills in interpreting and applying simulation results to practical engineering tasks, ensuring accurate and reliable equipment design.

Who this course is for:

Students, graduates and engineers who would like to learn process simulation who have no access to commercial process simulation software.

Students, graduates and engineers who would like to add a new simulation software skill to their curriculum.

Students, graduates and engineers interested on chemical engineering and plant design

More Info

https://rapidgator.net/file/0b79a9f0d396501b713e34fb8009eeb0/DWSIM.Process.Simulation.Mastering.the.Fundamentals.part1.rar

https://rapidgator.net/file/fbf8504ac84362cb75029056cb57587e/DWSIM.Process.Simulation.Mastering.the.Fundamentals.part2.rar

https://filestore.me/g4blyoyr4xpg/DWSIM.Process.Simulation.Mastering.the.Fundamentals.part1.rar

https://filestore.me/0jqrtqdda56u/DWSIM.Process.Simulation.Mastering.the.Fundamentals.part2.rar

What you'll learn

Be able to build, navigate and use different functions of DWSIM to build steady state process simulations.

Simulate a full process with vessel separator, compressor, pump, valve, pipe, heat exchanger and column

Understand process simulation under chemical engineer's point of view in plant design

Export heat and material balance for sizing of process equipment

Requirements

A background in chemical engineering (student, graduate or engineer) or allied engineering courses.

Notebook or desktop with internet connection (software will be provided for Windowns, MAC and Linux)

Description

This training program is designed to equip participants with the essential skills to effectively use DWSIM, a powerful chemical process simulation software. By the end of this course, participants will:

Build, Navigate, and Utilize DWSIM Functions:

Gain proficiency in constructing and managing steady-state process simulations using DWSIM.

Learn to navigate the user interface efficiently, exploring various tools and features to optimize workflow.

Master the use of different functions within DWSIM, enhancing simulation accuracy and efficiency.

Simulate a Full Process:

Develop the capability to simulate complete processes involving multiple unit operations.

Model a comprehensive process that includes essential equipment such as vessel separators, compressors, pumps, valves, pipes, heat exchangers, and columns.

Understand the interactions between different units and how to configure them within a simulation.

Understand Process Simulation from a Chemical Engineer's Perspective:

Acquire a thorough understanding of process simulation principles as applied to plant design.

Learn to analyze simulation results with a chemical engineer's insight, focusing on real-world applicability and design considerations.

Gain knowledge on how to optimize processes for efficiency, safety, and cost-effectiveness.

Export Heat and Material Balances for Equipment Sizing:

Learn to export detailed heat and material balance data from simulations.

Gain skills in interpreting and applying simulation results to practical engineering tasks, ensuring accurate and reliable equipment design.

Who this course is for:

Students, graduates and engineers who would like to learn process simulation who have no access to commercial process simulation software.

Students, graduates and engineers who would like to add a new simulation software skill to their curriculum.

Students, graduates and engineers interested on chemical engineering and plant design

More Info

https://rapidgator.net/file/0b79a9f0d396501b713e34fb8009eeb0/DWSIM.Process.Simulation.Mastering.the.Fundamentals.part1.rar

https://rapidgator.net/file/fbf8504ac84362cb75029056cb57587e/DWSIM.Process.Simulation.Mastering.the.Fundamentals.part2.rar

https://filestore.me/g4blyoyr4xpg/DWSIM.Process.Simulation.Mastering.the.Fundamentals.part1.rar

https://filestore.me/0jqrtqdda56u/DWSIM.Process.Simulation.Mastering.the.Fundamentals.part2.rar

Join to our telegram Group

Information

Users of Guests are not allowed to comment this publication.

Users of Guests are not allowed to comment this publication.

Choose Site Language

Recommended news

Commented

![eM Client Pro 9.2.1735 Multilingual [Updated]](https://pikky.net/medium/wXgc.png)

![Movavi Video Editor 24.0.2.0 Multilingual [ Updated]](https://pikky.net/medium/qhrc.png)