Most Commented

GibbsCAM 2025 v25.0.37.00 (x64)

Description material

File size: 2.23 GB

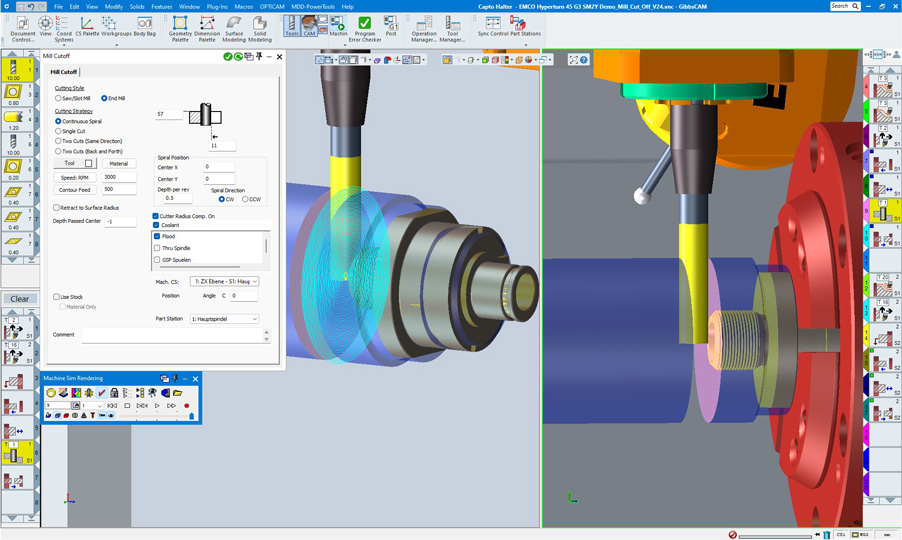

GibbsCAM 25 reinvents the way programmers use CAM software. With a balance of new features and interface enhancements, GibbsCAM 12 delivers a CAM solution that is perfect for both seasoned users and brand new programmers. GibbsCAM 25 introduces a modern, updated interface that is designed to increase user efficiency and improve the entire user experience.

Updated User Interface

The new user interface brings an up-to-date look and an ability to customize, along with ease-of-use features that users expect, all while maintaining the traditional GibbsCAM personality, character, and workflow. These changes modernize the GibbsCAM interface, making it more familiar and inviting to new users while preserving the powerful simplicity that experienced users to appreciate.

GibbsCAM 25 updated user interface

Redesigned command icons

More accessible Process list

Added locations for Do It and Redo buttons

Custom Processes are more easily accessible

Powerful command search

Interface Customization

Menus, toolbars, and palettes can be customized to optimize your workflow. Easily configure your workspace for quick access to the functions you use frequently. You can save an unlimited number of customizations, so that different users can quickly load the customized interface they prefer.

Add or subtract icons from toolbars

Create user defined toolbars

Un-docking and repositioning of toolbars

Resizable Tile lists

Switch between large and small tiles with two clicks

Multi-Part Machining Play Video

Easily duplicate part programs across multiple setups

Choose Equally Spaced, Grid, or manually define positions

Define tool motion between instances

Complete all operations for a single part, or one operation at a time across all parts

VoluTurn

The new VoluTurn option is the latest advancement in Ultra High Speed Machining for turning applications. It offers manufacturers the ability to significantly increase productivity by reducing cycle times while also reducing wear on cutting tools by creating constant-load toolpaths while turning with round turning tools.

5-Axis Machining For multi-axis machining applications, GibbsCAM 12 utilizes the latest technology of tool motion and part orientation to ensure the most productive programs and full machine tool utilization.

Define Clearance Area automatically

Maximize 3-Axis machining when doing porting

Set Check Tolerance for Gouge checking

SolidSurfacer

Automatic fixture avoidance

Enable Plunge lead-in

Link toolpaths using High Feedrate tool motion

Define minimum machined pocket size

More Entry/Exit control

Video Training

High-quality entry level training videos from Cognus are now accessible directly from the Help menu.

Complete instruction for Production Milling

Tutorial is made up of multiple five-minute videos

Materials such as detailed drawing files and example programs are included

Additional training for advanced modules is available for purchase from Cognus

Screen :

What's New

HOMEPAGE

https://www.gibbscam.com/en

Buy Premium Account From My Download Links & Get Fastest Speed.

Warning! You are not allowed to view this text.

Warning! You are not allowed to view this text.

Warning! You are not allowed to view this text.

Tags: GibbsCM

Join to our telegram Group

Information

Users of Guests are not allowed to comment this publication.

Users of Guests are not allowed to comment this publication.

Choose Site Language

Recommended news

Commented

![eM Client Pro 9.2.1735 Multilingual [Updated]](https://pikky.net/medium/wXgc.png)

![Movavi Video Editor 24.0.2.0 Multilingual [ Updated]](https://pikky.net/medium/qhrc.png)